BladeFix usage case on CFM56 5B engine

CFM56 5B - decision process to replace 3 damaged blades - W/O issued in under 10 minutes

Typical blade event

#1 engine ( CFM56 5B ) on an A320 in Luton suffers a bird strike on takeoff that results in 3 blades (14, 17 & 20) to be replaced before

returning to service. The aircraft has immediate access to 2 pairs of blades in Luton, these blades are also available to be used as single blades.

The decision has to be made to be made to wait for a 3rd pair of blades to be shipped in or to go ahead and try to use the 4 available blades to get the aircraft

back into service. It is quite possible that a powerplant engineer with experience of selecting and balancing a fan will fail to find a “solution” that will

allow the blades to be used and balance the fan within the AMM limitations.

It could take many hours of trying different combinations of existing blade position

swaps to achieve a result… by which time it would have been more efficient to ship in an additional blade pair. This also assumes that the existing blade parameters

for the fan are correct and easily accessible. The likely outcome is an AOG of 1 day or more… with all the associated operational pain and expense.

How BladeFix is used to handle this typical event

The local engineer/technician gives the operators powerplant engineers the blade position numbers that need replacing, they will then login to their BladeFix system from any available web browser and complete the following steps to automatically find a number of viable solutions…

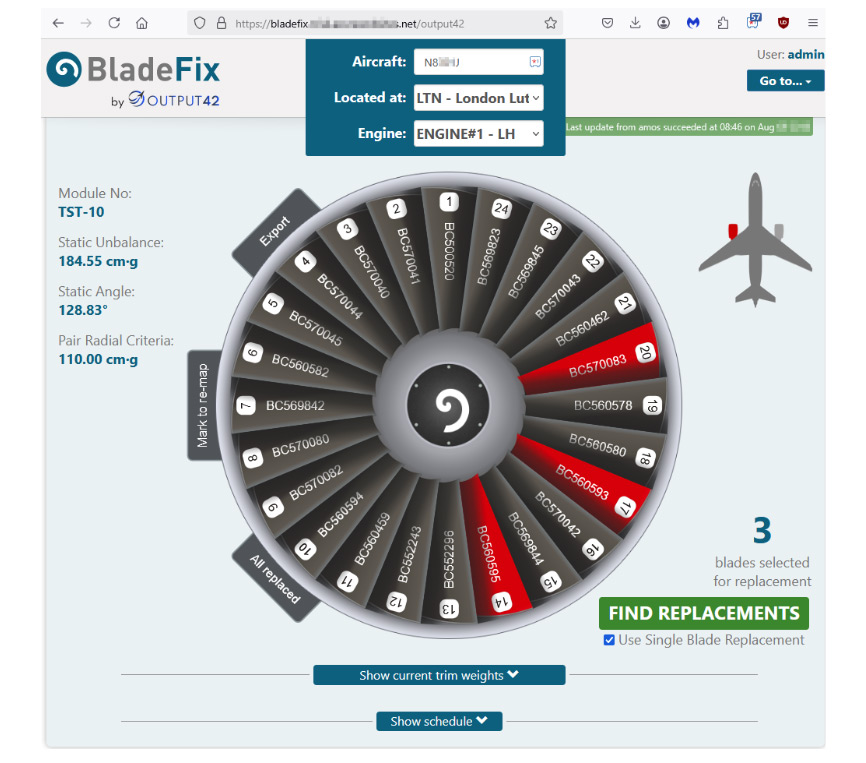

Step 1

Enter Aircraft Reg, airport location and Engine number

Step 2

Click on the 3 blades that need to be replaced

Make sure "Use single blade replacements" is ticked (default is pair replacement)

Step 3

Click on "FIND REPLACEMENTS"

… Make a coffee - it will take BladeFix 2 - 5 minutes to work it's magic.)

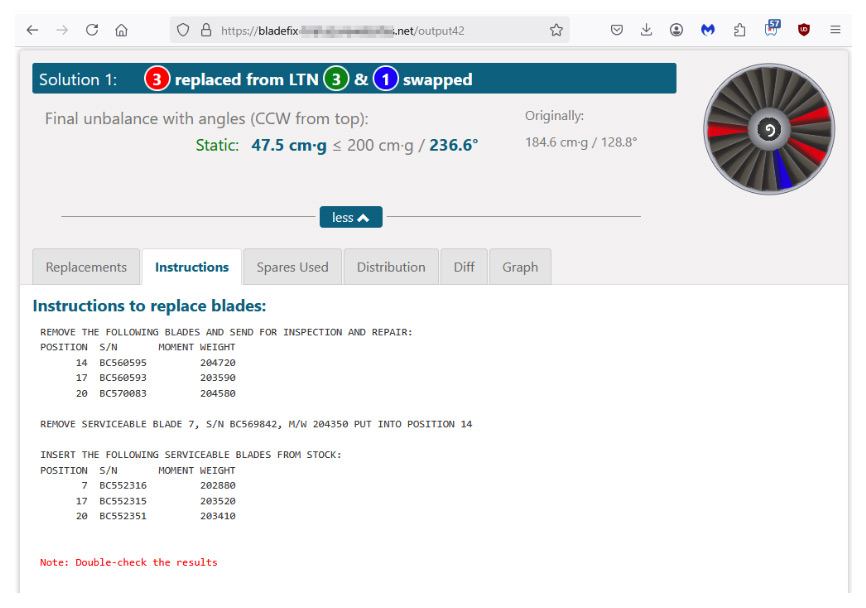

Step 4

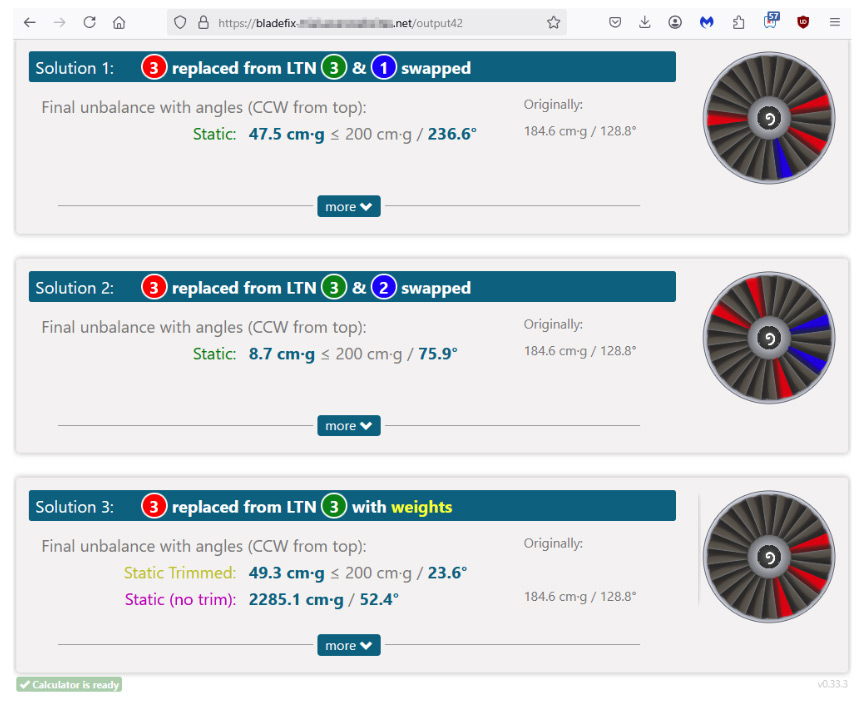

Up to 5 different blade replacement "Solutions" will be offered, fully complying with the AMM

The 1st solution is chosen as it usually has the minimum number of blade "swaps"

Step 5

The "Instructions" page containing all the details of the work to be carried out is "cut'n'pasted" into a Works Order and sent to the local engineer.

Step 6

The local engineer gets to work on replacing the blades.

The following screenshots show the key functionality used to find a solution.

NOTE: all engine fan blade data, blade stock and location data is stored and kept up to date on BladeFix cloud servers.

Engineer enters aircraft information and selects blades to be replaced.

3 viable "solutions" are offered, "Solution 1" is selected

“Instructions” from "Solution 1" are cut n pasted into a Works order.